Next-generation Advanced Cartesian Geometry EDXRF for Rapid Qualitative and Quantitative Elemental Analysis

Key Advantages & Features

NEX CG II Series, powerful second-generation energy dispersive X-ray fluorescence (EDXRF) spectrometers, deliver rapid qualitative and quantitative determination of major and minor atomic elements in a wide variety of sample types — from oils and liquids to solids, metals, polymers, powders, pastes, coatings, and thin films.

- Non-destructive elemental analysis for sodium (Na) to uranium (U)

- Rapid elemental analyses of solids, liquids, powders, coatings, and thin films

- Indirect excitation for exceptionally low detection limits

- High-power 50 kV 50 W (NEX CG II) or 65 kV 100 W (NEX CG II+) X-ray tube

- Large-area high-throughput silicon drift detector (SDD)

- Analysis in air, helium, or vacuum

- Powerful and easy to use QuantEZ® software with multilingual user interface

- Advanced RPF-SQX Fundamentals Parameters software featuring Scattering FP

- Rigaku Profile Fitting (RPF) advanced algorithm for peak deconvolution

- Various automatic sample changers accommodating up to 52 mm samples

- Low cost of ownership backed by a 2-year warranty

Video

Additional Notes

- Product Overview

- Application Notes

- NEX CG Legacy Docs

- Cartesian Geometry

Industrial Quality Control to Advanced Research Applications

The Rigaku NEX CG II Series are multi-element, multi-purpose analyzers, ideal for measuring ultra-low and trace element concentrations up to high weight percent levels. These analyzers serve many industries and are especially well-suited for semi-quantitative determination of elemental content in complete unknowns. Applications range from industrial and in-plant quality assurance to research and development. They are easy to use for non-technical operators yet powerful enough for expert use in commercial labs and R&D facilities. Users can achieve the lowest limits of detection and easily manage complex applications. NEX CG II Series are ideal for testing agricultural soils and plant materials, analyzing finished animal feeds, measuring waste oils, environmental monitoring, pharmaceuticals, cosmetics, and many others.

Achieve Superior Analytical Power with NEX CG II Series

NEX CG II Series achieve superior analytical power with either a 50 kV 50 W (NEX CG II) or 65 kV 100 W (NEX CG II+) end-window palladium-anode X-ray tube, five secondary targets covering the complete elemental range sodium through uranium (Na – U), and a high-throughput large-area silicon drift detector. Their unique optical kernel, combined with Rigaku’s advanced RPF-SQX Fundamental Parameters software, delivers the most sensitive EDXRF measurements in the industry.

Additionally, users can obtain high-throughput measurements with various autosampler options, accommodating 32-, 40-, and 52-mm samples. NEX CG II Series analyzers do not require cooling water or liquid nitrogen, and the enclosure measures 463 mm (W) × 492 mm (D) × 382 mm (H). This smaller footprint makes them an attractive instrument for any commercial lab or R&D facility. Available models are NEX CG II for excellent spectral resolution for trace peaks or NEX CG II+ for more demanding applications requiring a higher-powered system.

Featuring a 65 kV 100 W X-ray tube, NEX CG II+ performs trace element analysis for pharmaceutical materials, catalysts, cosmetics, monitoring for toxic metals in aerosols on air filters, as well as analyzing trace heavy metals and rare earth elements (REE), and other applications requiring a high degree of sensitivity.

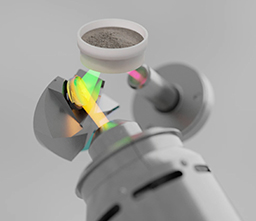

Cartesian Geometry and Polarization for Trace Level Sensitivity

Unlike conventional EDXRF spectrometers, NEX CG II Series are indirect excitation systems using secondary targets rather than tube filters. Monochromatic and polarized excitation from secondary targets vastly improves detection limits for elements in highly scattering matrices like water, hydrocarbons, and biological materials. Secondary target excitation in full 90° Cartesian Geometry eliminates background noise. As a result, NEX CG II Series bring a new level of analytical sensitivity to XRF technology. Users can measure ultra-low and trace element concentrations, even in challenging sample types.

Easy Instrument Control with Advanced Qualitative and Quantitative Analytical Software

NEX CG II Series analyzers are easy to use with QuantEZ, a powerful PC-based software providing intuitive instrument control with simple menu navigation and a customizable EZ Analysis interface. Users can maximize their time and productivity with simplified routine operations and create their own methods using a simple flow bar wizard. In addition, various software options are available to meet user needs, including SureDI, supporting compliance with 21 CFR Part 11.

RPF-SQX Reduces the Need for Standards

Advanced qualitative and quantitative analysis is powered by Rigaku’s RPF-SQX Fundamental Parameters (FP) software, featuring Rigaku Profile Fitting (RPF) technology and Scattering FP. This robust integrated software allows semi-quantitative analysis of almost all sample types without standards — and rigorous quantitative analysis with standards. Rigaku’s Scattering FP method automatically estimates the concentration of unmeasurable low atomic number elements (H to F) and provides appropriate corrections.

Calibration standards can be expensive and difficult to obtain for many applications. With RPF-SQX, the number of required standards is greatly reduced, significantly lowering the cost of ownership and reducing workload requirements for running routine analyses.

The following application notes are first-generation NEX CG legacy documents. They reflect the minimum performance achievable on the NEX CG II.

Unique 3D Cartesian Geometry Optical Kernel Dramatically Increases Peak-to-background Ratio

NEX CG II Series build on NEX CG’s legacy of using Cartesian Geometry and secondary targets for trace-level sensitivity. NEX CG II Series analyzers feature a unique and improved close-coupled Cartesian Geometry optical kernel that dramatically increases signal-to-noise ratio and delivers enhanced elemental analysis.

NEX CG II Series spectrometers are indirect excitation systems using secondary targets rather than tube filters. Indirect excitation eliminates background noise, resulting in the lowest limits of detection. These results are achieved with an end-window palladium-anode X-ray tube in either a 50 kV 50 W (NEX CG II) or a 65 kV 100 W (NEX CG II+) option, monochromatic or polarized excitation from 5 secondary targets, and a high-performance large-area silicon drift detector.

Users can acquire a spectrum with virtually no background noise using full 90° Cartesian Geometry and indirect excitation. Polychromatic X-rays from the X-ray tube irradiate the secondary target. The secondary target is excited and fluoresces, emitting monochromatic X-rays to the sample. The detector then records spectra from the sample.