Mining & Refining

EDXRF analyzers are a fast, simple, and powerful way for mining operations of all sizes to determine the elemental composition for a wide variety of sample types and materials. Whether the determination entails the measurement of ores, feed, slags, or tailings, EDXRF is one of the most used techniques for metal-bearing minerals and metals and their oxides. It plays a key role in various stages, from exploration to ore processing and monitoring.

You can easily streamline your mining and refining processes with EDXRF. Learn more about how our benchtop solutions can help you.

Why choose EDXRF?

Benchtop solutions

EDXRF offers a combination of affordability, ease of use, versatility, and speed, making it a cost-effective solution for mining operations. We offer a range of benchtops that are easy to use and suited for high-throughput settings. Here are some advantages of using EDXRF:

- Simple, fast, and non-destructive

EDXRF is non-destructive, allowing quick qualitative and quantitative elemental analysis without damaging your samples. It also provides faster turnaround times compared to other techniques. Operation is simple, even for non-technical personnel, and there is little to no sample preparation. You get results in minutes.

- Cost-effective and compact

EDXRF analyzers offer you a cost-effective solution. Generally, they are more affordable upfront and have lower operating costs over the lifetime of the instrument. Our benchtops do not require complex setups and are user-maintained. They are also compact and built rugged, which makes them ideal for on-site analysis or for situations where space is limited.

- Addresses a wide range of mining applications

EDXRF technology can be used for various applications, including analyzing ores, feeds, slags, concentrates, and tailings. Our analyzers are user-friendly and provide you with a versatile solution, whether you are screening samples at the mine site or processing facility or need a powerful system for work in a central lab.

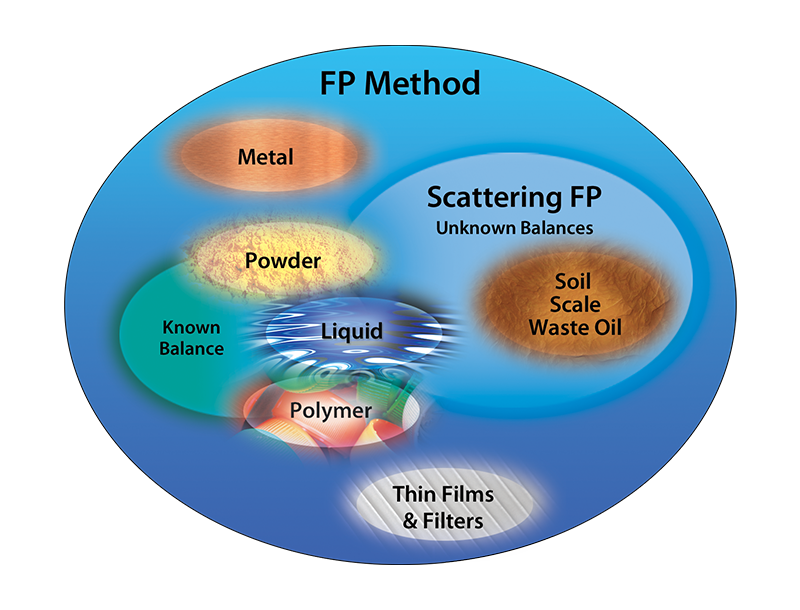

RPF-SQX Fundamental Parameters with Matching Libraries

Options are also available for semi-quantitative measurement for screening, identification, and other semi-quant needs without any assayed reference material using Rigaku’s RPF-SQX Fundamental Parameters (FP) software. With only a few assayed samples, this software also offers user-definable Matching Libraries, providing an easy way to match your XRF to your specific analysis needs.

Application examples

Explore our application examples to see if our solutions can benefit your needs

Other application examples

-

-

EDXRF1231 - NEX QC—Sulfur in Coal

-

EDXRF1255 - NEX QC—Sulfur in Gypsum

-

EDXRF1187 - NEX QC—Ti & Fe in Kaolin Clay

-

EDXRF1537 - NEX DE—Gold Processing

-

EDXRF1366 - NEX QC+—Analysis of Metals in Nickel Ore

-

EDXRF1352 - NEX QC+—Analysis of Clay

-

EDXRF1480 - NEX QC+—Analysis of Iron Concentrates

-

EDXRF1587 - NEX QC+—MgO & P₂O₅ in Phosphate Rock

Solutions for mining and refining needs

For routine analysis NEX QC Series

Recommended when you need an affordable system for identifying and quantifying the elemental composition of your materials. These compact systems offer exceptional value for analyzing a wide range of sample types. They are designed for ease of use, even for non-technical operators.

_picture_2020.06.25.png)

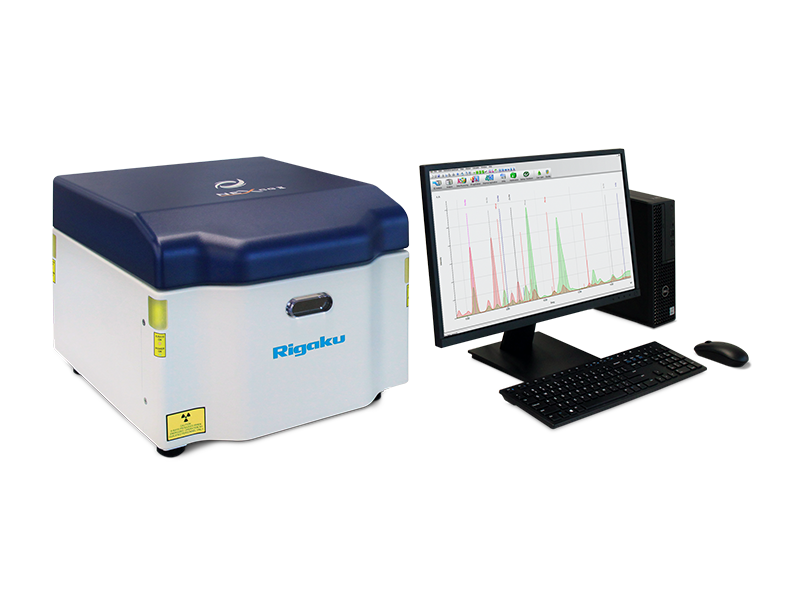

For high-performance analysis NEX DE Series

Recommended when you need expanded capabilities, including higher sample batch throughput, small spot analysis, or enhanced performance for measurement of higher atomic number elements. These systems provide quick elemental identification, screening, and characterization of your materials. RPF-SQX Fundamental Parameters with Matching Libraries are also available with these systems.

_picture_29_2024.09.23.png)

For trace elemental analysis NEX CG II Series

Recommended when you need enhanced sensitivity. These systems are ideal for trace-level performance applications, such as processing precious metals. If desired, semi-quantitative analysis can be made using Rigaku RPF-SQX Fundamental Parameters without any assayed reference material for screening and characterization.

Information and resources

- American Institute of Mining, Metallurgical, and Petroleum Engineers (AIME)

- Australasian Institute of Mining and Metallurgy (AusIMM)

- California Geological Survey

- Canadian Institute of Mining, Metallurgy & Petroleum (CIM)

- Info-Mine

- Mining Industry Information Database

- Mining Technology

- Mining & Metallurgical Society of America (MMSA)

- National Mining Association (NMA)

- Society for Mining, Metallurgy, and Exploration (SME)

- The Minerals, Metals and Materials Society (TMS)

- U.S. Bureau of Land Management

- U.S. Geological Survey

- Wikipedia: Mining

- Wikipedia: Refining

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.