Elemental Analysis by EDXRF

Applied Rigaku Technologies

Applied Rigaku Technologies specializes in EDXRF (energy dispersive X-ray fluorescence) instrumentation and offers benchtop and process control systems for analyzing solids, liquids, powders, coatings, and thin films.

Elemental analysis by EDXRF allows you to measure and monitor elements in almost any sample type. Whether you are improving the quality of products or optimizing industrial processes, we understand getting quick, high-quality results while also managing costs is critical.

Specializing in EDXRF technology

Applied Rigaku Technologies provides advanced, high-quality EDXRF analyzers and offers customer-focused solutions and support backed by Rigaku innovation and years of EDXRF experience.

Products

You can measure a wide range of atomic elements with detection limits from low ppm to high weight percent. EDXRF may also be used to measure the thickness and composition of coatings and multi-layer thin films.

NEX CG II Series

High-performance indirect excitation EDXRF for complex applications with trace elements and variable base matrices

Learn moreNEX DE Series

High-power 60 kV EDXRF systems delivering speed, precision, and small spot measurements

Learn moreNEX QC Series

Combines quality, affordability, and performance for a wide range of applications

Learn moreWhat matters most?

Finding the right instrument that meets your analytical needs and budget. From basic entry-level to high-end performance, we can help you find the right solution.

Your time

Get rapid results with minimal to no sample prep. Analyze multiple elements with an easy-to-use system.

Your samples

Samples are preserved, not consumed or destroyed. EDXRF is a non-destructive technique.

Your costs

EDXRF offers a cost-effective solution for elemental analysis. Systems are self-installed and maintained and do not require expensive consumables.

Application examples

Do you have time-sensitive applications? Do you need to analyze a sample without destroying it? Are your applications complex with trace elements and variable base matrices? EDXRF is a quick and easy technique that serves many applications.

Connect with us

Are you going to a conference or tradeshow soon? If so, you can discuss your specific applications and requirements with our experts and see our analyzers for a live demonstration.

Who analyzes?

Many industries and organizations use Rigaku EDXRF elemental analyzers to solve their analytical needs.

Silicone coatings

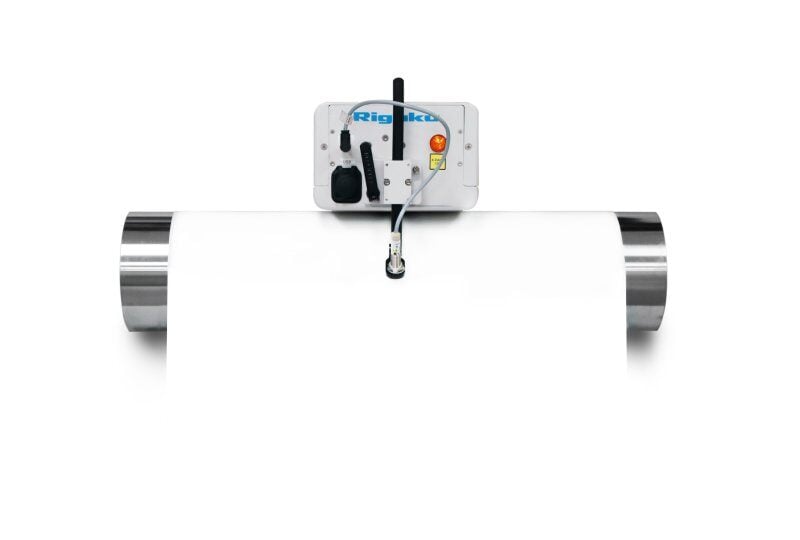

EDXRF helps silicone coaters maintain consistent product quality, minimizing waste and product rejection for siliconized papers and films. Our at-line and in-line solutions are invaluable tools for roll-to-roll manufacturers.

Learn more >

Petroleum

EDXRF offers the flexibility and reliability to monitor sulfur, chlorine, metals, and other critical elements. Our instruments serve upstream and midstream for in-field use and downstream for refineries and commercial labs.

Learn more >

Mining

EDXRF is a simple yet powerful method for identifying and quantifying the elemental composition of a wide variety of materials. It provides excellent sensitivity and performance for at-line control and quality checks in mining processes.

Learn more >

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.